Not Found

The page you’re looking for has been deleted, or the product you’re searching for is discontinued. Please Contact Us if you’ve any questions. Thanks.

Browse Hottest Products

-

FIFISH E-GO E200A Underwater Robot

$7,348.00 Supplier: Qysea

-

FIFISH E-GO E100 Underwater Robot

$6,499.00 Supplier: Qysea

-

JetRover ROS Robot Car with Robot Arm Powered by Jetson Nano – Standard Kit, Track, G4 Lidar

$1,360.99 Supplier: Hiwonder

-

JetRover ROS Robot Car with Robot Arm Powered by Jetson Nano – Developer Kit, Mecanum, G4 Lidar

$1,617.99 Supplier: Hiwonder

-

Oscal Powermax 3600 Portable Power Station

Sale! $1,699.00 Supplier: Oscal

-

Oscal 300L Trolley Foldable Wagon for Long-Lasting Efficient Transport

Sale! $139.00 Supplier: Oscal

-

GTR Simulator GTA Revolution – Adjustable Racing Cockpit With Leatherette Pista Black/Red Seat

Sale! $1,299.99 Supplier: Abtivan

-

GTR Simulator GTA Revolution – Adjustable Racing Cockpit With Leatherette Pista Black and Blue Seat

Sale! $1,299.99 Supplier: Abtivan

-

3D LiDAR 256 Lines Point Cloud Benewake AD2-S-X3 Long Range 350m for ADAS Autonomous Driving Truck

Sale! $7,999.00 Supplier: Benewake

-

OSCAL Pad 10 WiFi 10.1 Inch Tablet (8+128GB) 1TB Expansion, Android 12 Tablet Computer

$101.99 Supplier: Oscal

-

OSCAL Newest 2024 Pad 70 Tablet with 4GB+128GB and 10.1-inch Latest Tablet with 13MP Dual Camera and WiFi

$81.99 Supplier: Oscal

-

Enskate R2 Electric Skateboard Longboard with Remote Controller, 22mph Top Speed, 900W Dual Motor

Sale! $389.00 Supplier: EnSkate

-

Enskate Electric Skateboard Longboard R3 with Wireless Remote Control, Maximum Range Of 22 Miles

$569.00 Supplier: EnSkate

-

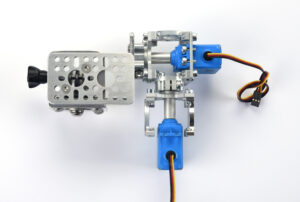

Waterproof Pan Tilt Mechanism – PT MECH-H2O

$799.00 Supplier: Inspectorbots

-

6.5 Inch Lamborghini Hoverboard with Lights and App Two-Wheel Self Balancing Scooter

$259.00 Supplier: Asiwo

-

All-Terrain Hoverboard 8.5″ Big Wheel Self Balancing Scooter with Bluetooth and LED Lights

$279.00 Supplier: Asiwo