Magnetic and Electric Field Modeling Software – EMS Electromagnetic Simulation

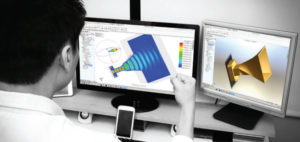

EMS is an electromagnetic field simulation software that calculates fields (electric/magnetic / flux / potential / eddy currents), circuit parameters (inductance/capacitance/resistance/impedance/flux linkage), mechanical parameters (force/torque), and losses (eddy/core/hysteresis/ohmic).

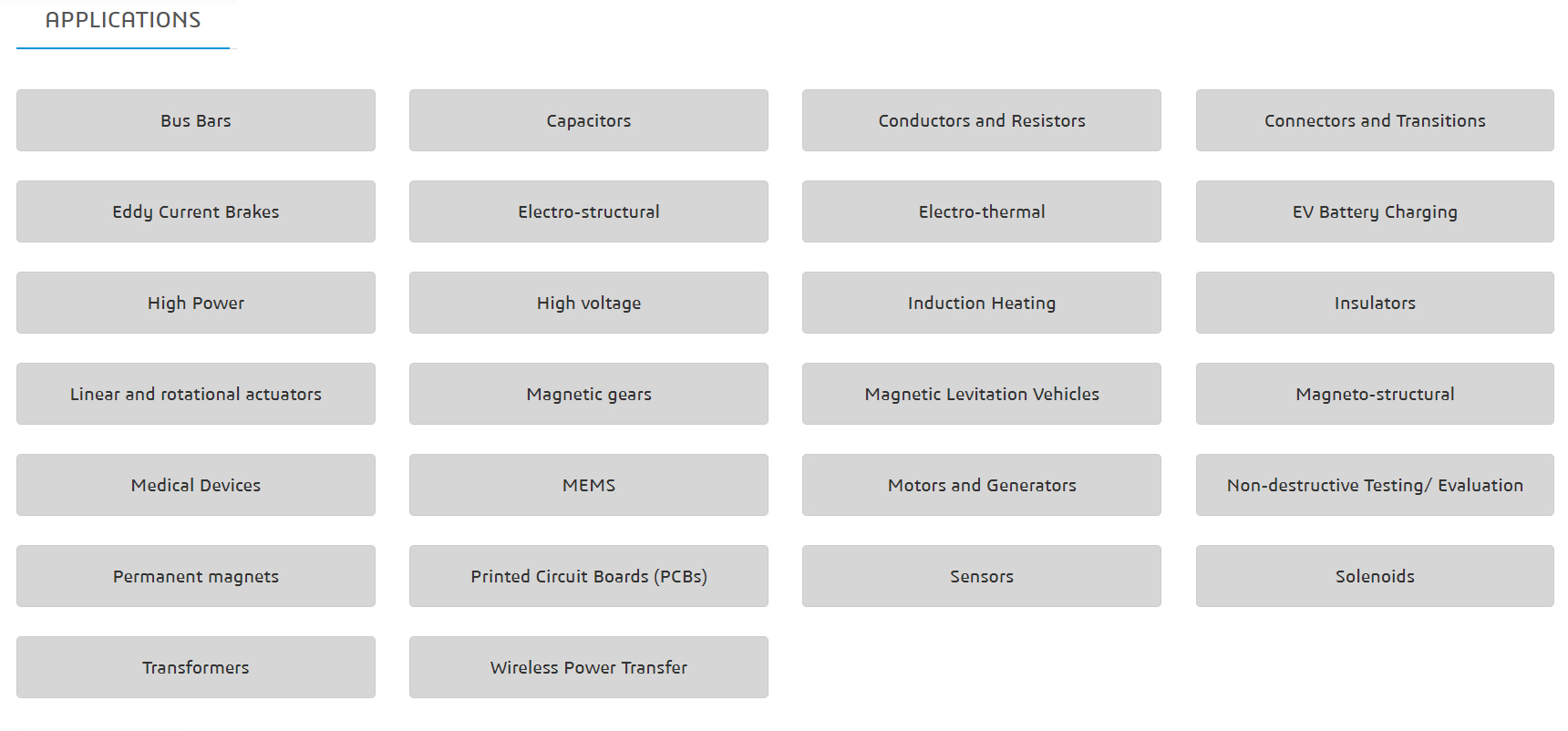

EMS is a Gold Certified Add-in to SOLIDWORKS® and an Add-in to Autodesk® Inventor® which enables you to simulate the most intricate electrical machines, motors, generators, sensors, transformers, high voltage apparatus, high power machines, electrical switches, valves, actuators, PCB’s, levitation machines, loudspeakers, permanent magnet machines, NDT equipment, inverters, converters, bus bars, inductors, bushings, or biomedical equipment.

Main Features and capabilities

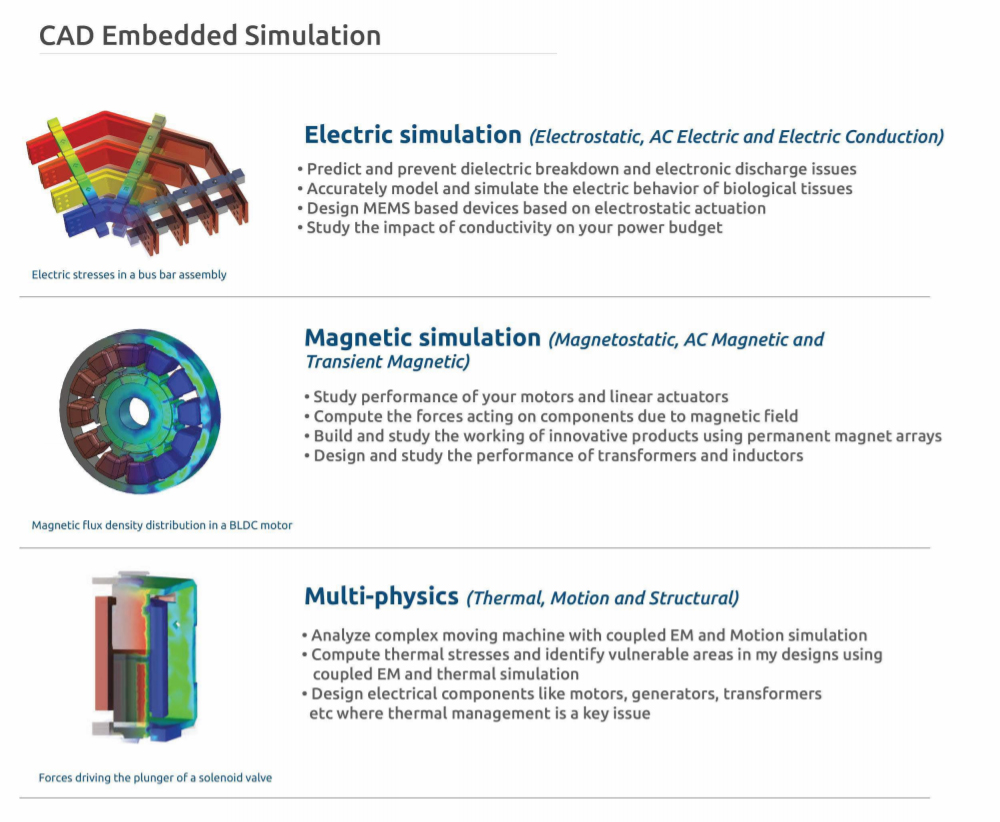

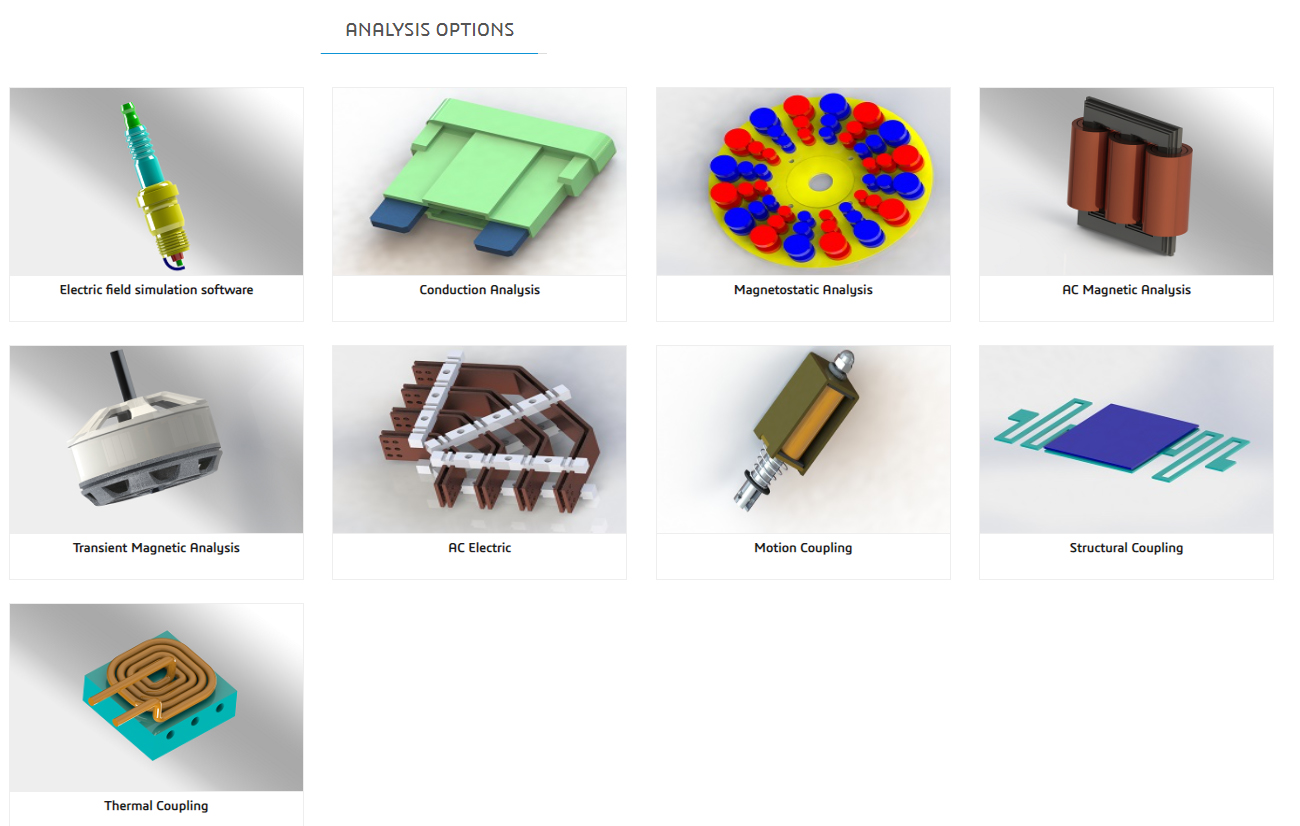

Full 3D electromagnetic field simulation: EMS enables you to do electric and magnetic simulations using your complete 3D geometry to ensure your designs’ 100% accuracy and integrity. EMS also allows you to do 2D planar and axis-symmetry simulations for designs where such simplification yields significantly reduced time for a solution with no compromise on accuracy.

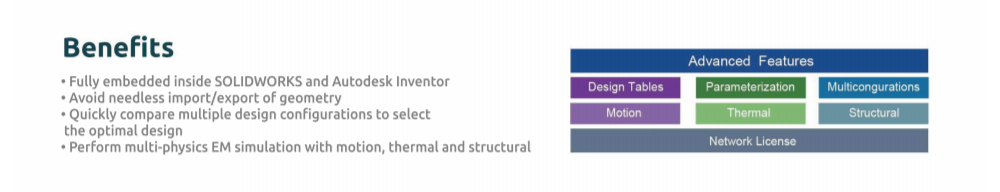

Seamless integration with CAD geometry: EMS seamless integration in the two leading CAD platforms – SOLIDWORKS and Autodesk® Inventor® empowers you to simulate the most intricate electromagnetic designs. You don’t need to “reinvent the wheel” acquire a CAD model from the mechanical drafting personnel and instantly start your electric or magnetic simulation without any modification.

Parametric simulation: EMS enables numerous What if? Analyses to obtain the best design for your application. Any CAD dimension or a simulation variable can be set as a parameter to study the effect of its changes on your design. This serves as a first step to optimizing your designs.

Multiphysics capabilities: EMS is an accurate multiphysics software that enables you to couple your magnetic and electrical design to Circuit, Motion, Thermal, and Structural analyses on the same model in a hassle-free integrated environment without any need to import/export any data. This integrated multiphysics environment brings user efficiency, accuracy, and productivity.

User-friendly interface and embedded learning materials: It is an easy-to-use program with a very short learning curve. Follows the same philosophy of your CAD software. The demo viewer feature in the software gives you access to numerous training materials for fast learning and adoption of EMS.

FEATURES

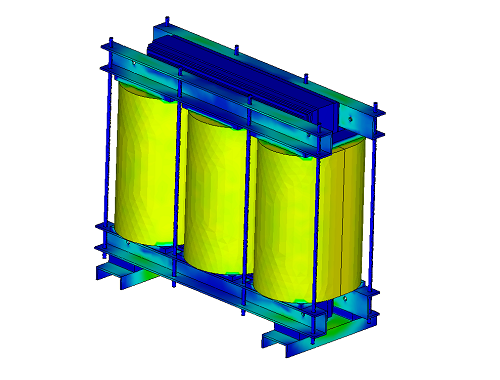

A Transformer Software and a Calculator

EMS can be used as a transformer design software. EMS can be used to study critical transformer design parameters, including virtually

Energy storage

A transformer shall not store energy but transfer instantaneously from input to output. Unfortunately, in real life, transformers store some undesired energy. EMS computes the leakage inductance representing the stored energy between windings regions occupied by non-magnetic media. Similarly, EMS calculates the mutual inductance, indicating the amount of undesired stored energy in the magnetic core and small air gaps.

Losses and thermal management

EMS can calculate the maximum “hot spot” temperature rise at the core surface inside the center of the winding. This calculation helps determine the smallest core size that meets the required power supply efficiency without exceeding the maximum “hot spot” temperature. To calculate the temperature rise, EMS considers all transformer losses, including eddy loss, hysteresis loss, core loss, winding loss, heat loss, and the surrounding liquid temperature and convection properties.

Core selection

EMS calculates the magnetic flux density and saturation levels in the core, which can help select the proper core material, shape, and size for any frequency and desired power output. The transformer’s designer ultimately aims to choose a shape that is easy to manufacture, as small of a core size as possible, and the least expensive core material while respecting the required power without saturating the core.

Open and short-circuit tests.

Open and short circuit tests of a transformer are critical but costly and time-consuming. EMS enables the designer to run these tests accurately and efficiently virtually.

Insulation coordination

EMS calculates the dielectric breakdown, which is instrumental in selecting the proper bushings, surge arrestors, and other insulating infrastructure. This type of calculation helps the designer meet the various insulation coordination standards.

Short-circuit forces

EMS calculates the magnetic force acting on the windings and the core material and the stress and structural displacement due to these forces. This type of calculation helps guarantee the structural integrity of the transformer.

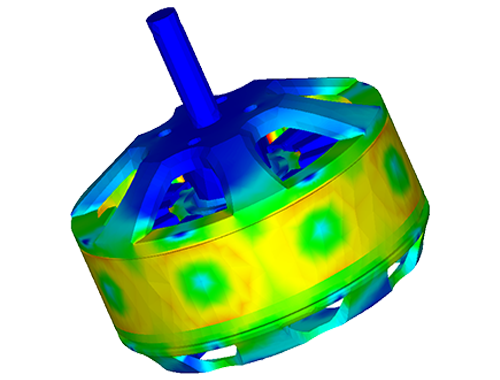

A Motor Software and a Calculator

EMS can be used as motor design software and can be used to study critical electric motor design parameters, including virtually

Parameters estimation

Winding inductance and resistance play a significant role in electrical motors’ control and state estimation. An example would be phase current control in an SRM motor or rotor position estimation in a sensor-less BLDC. EMS can determine these parameter values for a desired frequency set and current conditions.

3D modeling problems

- EMS is a complete 3D modeling platform. This enables the simulation of some important topologies and effects which are otherwise impossible to analyze:

- Skewing of slots or rotor poles is a common technique for cogging force reduction. Its results can be estimated only if the interaction between the stator and rotor is captured in all three dimensions.

- Advanced machine topologies such as axial and transverse flux machines inherently operate with 3D flux distribution and should be treated as such.

- End windings have a significant effect on the winding resistance, as well as its leakage inductance.

Torque

EMS can compute transient and steady-state torque profiles for various electrical machine topologies such as Permanent magnet AC machine, BLDC, Switched Reluctance, Induction, etc. Torque results for different rotor RPMs and winding currents determine the optimal operating conditions. Furthermore, EMS helps minimize the cogging torque by comparing its magnitude for different air gap lengths or fractional slot pitches.

Core material

Successful machine design depends on accurately representing nonlinear phenomena in the core material, such as flux saturation, eddy current, and hysteresis losses. EMS comes with a library of predefined solid and laminated core materials. The designer can easily compare materials regarding saturation, core losses, and overall efficiency. Core and winding loss results can be coupled with EMS’s thermal solver and determine temperature rise and cooling requirements.

Shape and sizing

Machine radius, length, and the number of poles will significantly determine its torque and power rating. However, finer geometrical features of the magnetic circuit profoundly affect machine performance. For example, the shape of squirrel cage bars in an Induction motor will affect how torque changes with the rotor slip. All these parameters can be readily varied inside EMS to evaluate their effect on the performance of the motor.

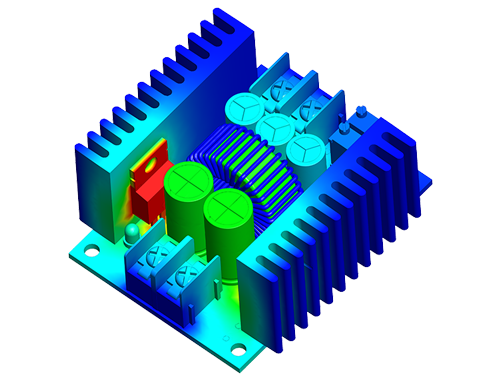

Parasitic RLC Extraction

EMS can be used as a parasitic RLC extractor. That is, it accurately calculates the resistance, the inductance, and the capacitance for any arbitrary 3D electric and electronics structure. These calculations consider the proximity effect, the skin effect, the dielectric and ohmic loss, and the frequency dependence. In other words, both DC and AC parasitic RLC are calculated. These parasitic values are instrumental in modeling various electric and electronic devices and circuits, including:

High-speed electronics

RLC models for high-speed electronic devices such as ICs, PCBs, packages, and on-chip passive components are crucial in studying crosstalk and distortion, interconnect delays and ringing, and ground bounce.

Power converters

RLC models are helpful in simulating power electronic equipment such as bus bars, cables, inverters, and converters commonly found in power distribution applications and hybrid and electric vehicles.

Touchscreen modeling

The modeling of touchscreens found in today’s smartphones and computers heavily depends on the accurate calculation of the capacitance of the screen wires.

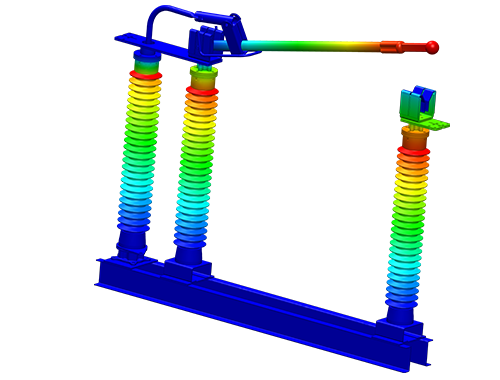

NDT simulation software

Electromagnetic fields and waves are widely used in non-destructive testing technologies. Because EMS accurately calculates the magnetic flux and eddy current, it covers a wide varies of electromagnetic NDT techniques, including eddy-current testing (ECT), magnetic flux leakage (MFL), remote field testing (RFT), magnetic particle inspection (MPI), pulses eddy current (PEC), and the alternating current field measurement (ACFM). NDT screening commonly involves the movement of the NDT probes. EMS is well-suited to model this type of motion since EMS couples to Solidworks Motion.

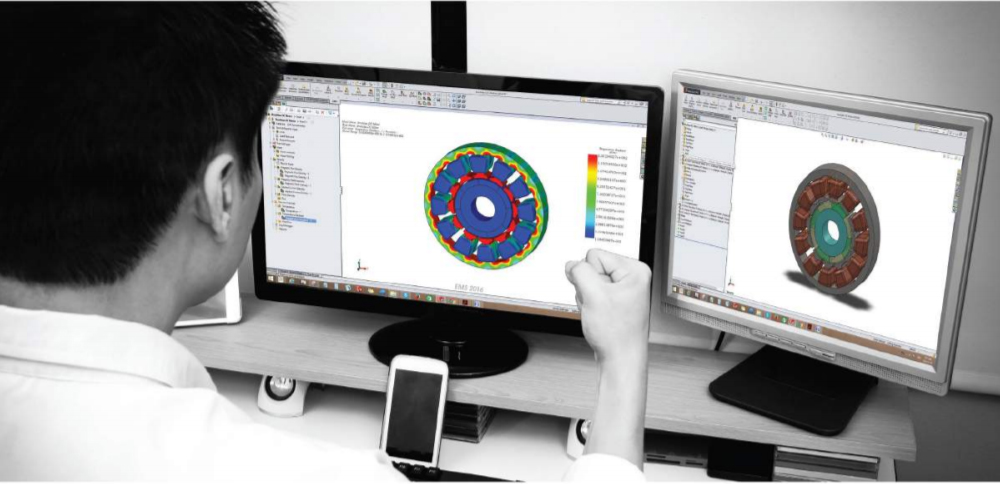

Solidworks and Autodesk Inventor Seamless Integration

EMS seamless integration in the three leading CAD platforms empowers you to simulate the most intricate electrical machine, motor, generator, sensor, transformer, high voltage apparatus, high power machine, electrical switch, valve, actuator, PCB, levitation machine, loudspeaker, permanent magnet machine, NDT equipment, inverter, converter, bus bar, inductor, bushings, or biomedical equipment. You don’t need to “reinvent the wheel,” acquire a CAD model from the mechanical drafting personnel, and start your magnet or magnetic simulation instantly without any modification. If you wish to modify the acquired CAD model, you won’t need to return to the drafting personnel because commercial CAD packages such as Solidworks are parametric and hierarchical. Change it yourself “on the fly”. If the drafting department or colleague uses a different CAD package, they can save it for you in Parasolid, ACIS, IGES, STEP, STL, CATIA, or ProE kernel. Then, import it into SOLIDWORKS®, Autodesk® Inventor®, or Ansys SpaceClaim and continue your electromagnetic design.

Multiphysics Capabilities

EMS is an accurate multiphysics software and simulation package. It enables you to couple your magnet, magnetic, and electrical design to Thermal, Structural, and Motion analyses on the same model and mesh in a hassle-free integrated environment without any need to import or export any data. This integrated multiphysics environment means no cluttering, jumping around, mishmash, chaos, confusion, and mess. It also means efficiency, accuracy, and productivity.

Electro-Thermal Analysis

Does your design involve electro-thermal aspects? Easy and hands-free! Just check “Couple to thermal” steady-state or transient in the study properties. EMS automatically computes the joule, eddy, and core losses and feeds them into the thermal solver. You may readily add non-electromagnetic heat loadings by applying volume heat, heat flux, or fixed temperature. Considering the environmental conditions such as convection and radiation, EMS thermal steady-state or transient computes the temperature, temperature gradient, and heat flux and saves them to the “Thermal Results” folder.

Electro-Structural Analysis

The electro-mechanical coupling is also easy and hands-free. The “Couple to structural” option invokes the EMS structural solver after transferring the local force distribution in relevant parts in addition to the mechanical loads and constraints and then computing the displacements. The stress and strain are subsequently deduced and added to the “Structural Results” folder. If the more general electro-thermo-mechanical coupling is desired, EMS transfers thermal and structural loads to the Thermal and Structural solvers. The Thermal solver, in turn, feeds the thermal loads to the Structural solver, which computes the final displacements that reflect both the electromagnetic and the thermal loads while considering the magnetic, electrical, thermal, and structural environments.

Solidworks Motion integration

Electrical machines and drives usually encompass moving parts and components. Generally speaking, the resulting motion is rotational, such as motors, or translational, such as linear actuators. Nevertheless, some applications, such as MagLev and Eddy’s current braking, may provoke all the motion six degrees of freedom. In such cases, only EMS can handle such intricate machines and equipment. Why? Because of EMS, it couples to the most versatile and powerful mechanical motion package, Solidworks Motion®. To find out more about this robust package, please visit https://www.solidworks.com/sw/products/simulation/motion-analysis.htm. The coupling to SolidWorks Motion® is again hassle-free. After creating a SolidWorks Motion® study, instruct EMS to couple to it. That is it, and that is all.

Grabcad, 3dcontencentral, trace parts

In recent years, millions of free 3D CAD models have become available in CAD depositories such as grabcad.com, www.3dcontentcentral.com, and www.traceparts.com. Consequently, you can grab a CAD model from the depositories, make necessary changes, and instantly start your finite element analysis.

EMS Results

EMS empowers you, the designer, to compute electric, magnetic, mechanical, and thermal parameters, including:

Electric Force

Electric Torque

Magnetic Force

Magnetic Torque

Electromagnetic Force

Electromagnetic Torque

Magnetic Flux Density

Magnetic Field

Electric Field

Electric Flux

Current Flow

Eddy Current

Inductance

Capacitance

Resistance

Hysteresis loss

Eddy loss

Speed

Acceleration

Stress

Flux Linkage

Core Loss

Breakdown Voltage

Lorentz Force

Lorentz Torque

Skin effect

Proximity effect

Magnetic Saturation

Induced Voltage

Force Density

Power Loss

Temperature

Temperature Gradient

Heat Flux

Back EMF

Electric flux density

Impedance

Ohmic loss

Displacement

Strain

Reviews

There are no reviews yet.