Not Found

The page or the product you are looking for is no longer available. Please see other products: https://ozrobotics.com/shop/

Browse Hottest Products

-

375 lb Electric Material Lift Stacker Motorized Hand Trucks Dolly Moving Cart, Max Lift Height of Loading Plate XSTO LFC170F3

$2,650.00 Brand: XSTO Stair Climbers

-

Electric Platform Trucks, Foldable Push Cart Dolly 661 LBS Capacity, 1000W Powered Heavy Duty Flatbed Cart with 360° Swivel Wheels for Warehouse Material Handling ET300P2

$1,599.99 Brand: XSTO Stair Climbers

-

Adeept PiCar Pro V2 AI Powered Robot Kit (Raspberry Pi NOT Included)

Sale! Original price was: $199.99.$164.99Current price is: $164.99. Brand: Adeept

-

Hiwonder LeRobot SO-ARM101 Open Source 6 Axis Robotic Arm (Advanced Kit/Assembled)

$519.99 Brand: Hiwonder

-

Hiwonder LeRobot SO-ARM101 Open Source 6 Axis Robotic Arm (Standard Kit/Assembled)

$474.99 Brand: Hiwonder

-

Hiwonder LeRobot SO-ARM101 Open Source 6 Axis Robotic Arm (Starter Kit/Assembled)

$440.99 Brand: Hiwonder

-

ACEBOTT Smart Robot Car Kit Compatible with Arduino IDE Programming STEM Education Coding Kit

$108.98 Brand: ACEBOTT

-

ACEBOTT STEM ESP8266 Arduino Compatible Spider Robot Kit for Robotics Projects

$99.98 Brand: ACEBOTT

-

Rundeer Electric Bike Engineered for Adventure and Athletic Performance

Sale! Price range: $2,099.00 through $2,199.00 Brand: RUNDEER

-

Robot Eilik – Touch Interactive Cute Robot with Abundant Emotions – Blue

Sale! Original price was: $149.90.$139.90Current price is: $139.90. Brand: Energize Lab

-

Mini Motorcycle Electric Riding Toy Car Bike with Speaker and LED Lights for Kids – Cruiser 12 Plus

Sale! Original price was: $499.00.$459.00Current price is: $459.00. Brand: Asiwo

-

Robot Eilik – Touch Interactive Cute Robot with Abundant Emotions – Pink

Sale! Original price was: $149.90.$139.90Current price is: $139.90. Brand: Energize Lab

-

Motorized Stair Climbing Shopping Cart – ZW030

$299.99 Brand: XSTO Stair Climbers

-

NordicSemi Wi-Fi 6 + Bluetooth LE 5.4 Dual Module-AN02P53P

$10.28 Brand: Raytac Corporation

-

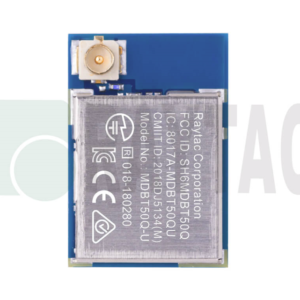

Bluetooth Low Energy BLE Module MDBT50Q-U1MV2

$8.50 Brand: Raytac Corporation

-

4 x 100W Class D Bluetooth Audio Amplifier Board – TSA8498B Apt-X

$65.45 Brand: TinySine

-

Stealth Pan Tilt Minibot – Tactical Inspection Robot

$7,750.00 Brand: Inspector Bots

-

Pan Tilt Minibot – Industrial Inspection Robot

$5,490.00 Brand: Inspector Bots