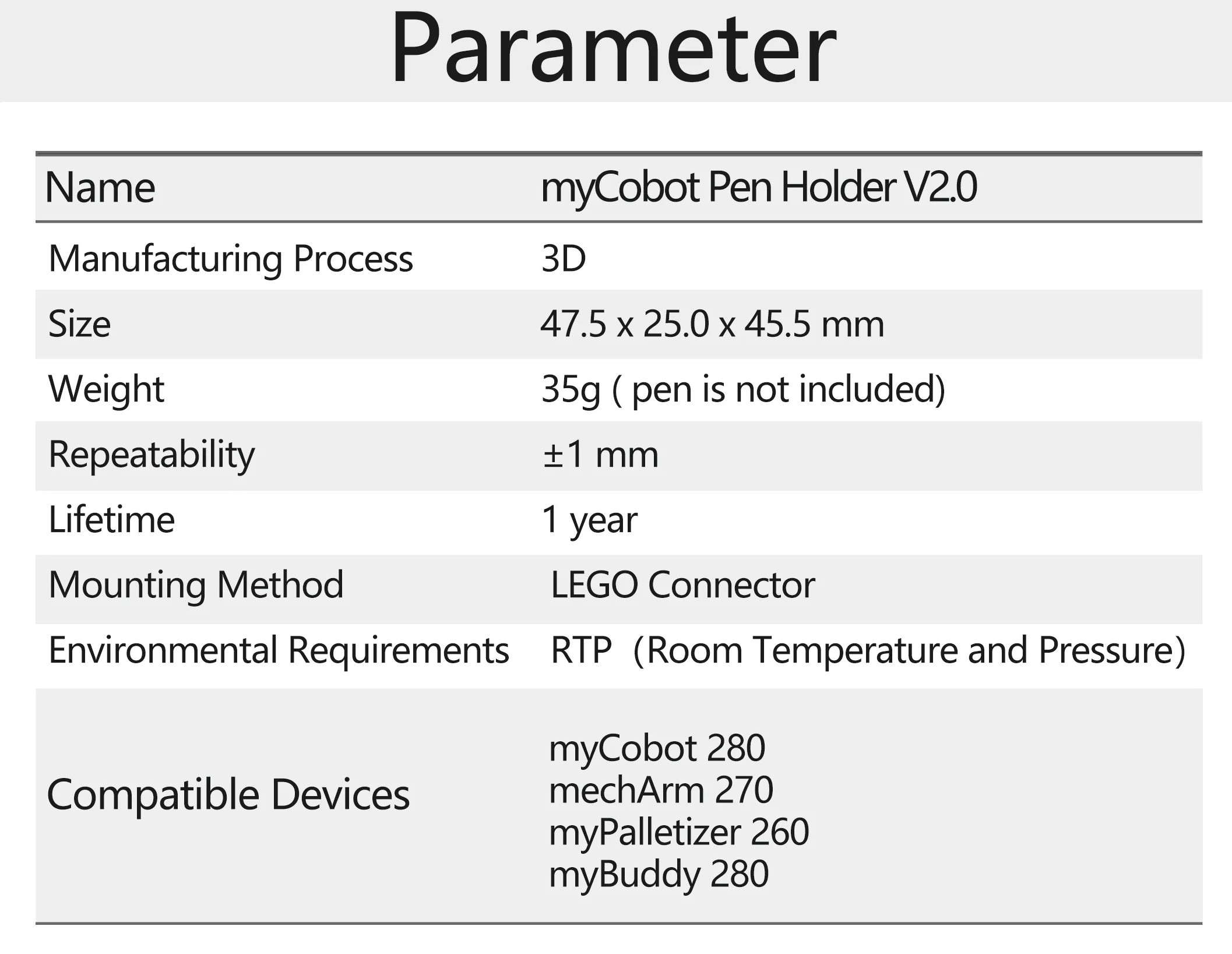

Pen Holder V2.0 for Elephant Robotics myCobot, myPalletizer, mechArm and myBuddy

myCobot Pen Holder is suitable for robot painting, flexible installation, and a built-in movable module. It supports the up-and-down movement of the end effector. It can be used for myCobot 280 M5Stack myCobot 280 Pi, MyCobot 280 For Arduino, myCobot 280 Jetson Nano, myPalletizer 260 M5Stack. Palletizer 260 Pi, mechArm 270 M5, mechArm 270 Pi, and my buddy.

Features

- Adaptive: The pen holder accessory can accommodate pens of different sizes and shapes for stable gripping, making it suitable for various pens.

- Safe and reliable: The pen holder accessory is made of flexible materials, which prevents pens from being damaged or slipping and ensures safe and reliable gripping.

- Convenient operation: The pen holder accessory can be quickly replaced and is suitable for different sizes and shapes. The gripping method is very flexible.

- Widely used: Mechanical arm pen holder accessories have broad applications in electronic manufacturing, precision assembly, biomedicine, and other fields. They are a convenient mechanical arm-end effector accessory.

Frequently Asked Questions

Q1: Does it support secondary development of functions?

Answer: Of course. You can use our API (Python, C++, C#, Javascript) to control myCobot directly or remotely or dive directly into the open-source ROS code.

Q2: What you can learn?

Answer: With myCobot M5, you can learn that Hardware: Embedded Microcontroller Based on ESP32, Motor and Steering Gear, M5Stack Basic/ Atom; Software: Arduino, UiFlow, Myblockly, Mind+, RoboFlow, C#, C++, Python, Javascript, ROS, MoveIt, Communication Data, Virtual Machines & Linux (visual system). With myCobot Pi and myArm, you can learn that Hardware: microprocessor, motor, and steering gear; Software: Myblockly, Mind+, RoboFlow, C#, C++, Python, Javascript, ROS, MoveIt.

Q3: How long it lasts?

Answer: It uses adapter power instead of battery power. As long as there is a power supply, it can continuously work. However, we should not keep it working for a long time. Just like when using a computer, it is sometimes better to let it rest.

Q4: How much weight can it lift / grip?

Answer: myArm 300 PI 2023:The payload is 200g, and the working range is 300mm. myCobot 280: The net weight of myCobot is 850g, the payload is 250g, and the working range is 280mm. myCobot 320:The net weight of myCobot is 3.5kg, the payload is 1kg, and the working range is 320mm. myCobot 260:The net weight of myPalletizer is 960g, the payload is 300g, and the working range is 260mm. myCobot Pro 600:The net weight of myCobot Pro is 8.8kg, the payload is 2kg, and the working range is 600mm.

Q5: What is the warranty on this?

Answer: We offer return and warranty services. Return service is limited to goods not opened within 7 days of the logistics receipt date. The customer bears the freight or other risks of returning the product. During the product period, the company only repairs malfunctions during normal robot use for free. For more warranty information, please visit the product details page.

Q6: How long will shipping take after I place the order? And What kind of logistics?

Answer: We ship worldwide and use the following carriers: FedEx、UPS 、DHL. International Express shall deliver the products within 1-2 weeks. All products use standard cartons and specially customized super hard paper shells to fix the products and prevent damage from impact firmly.

Q7: I don’t know how to develop a robot arm. Is there a graphical interface for operations?

Answer: For non-technical players, myCobot and myArm support the drag teaching function, which allows you to teach every action and instruction you want. Remove the traditional path point storage mode; no programming is required. The saved path can be recorded, and different paths can be saved for as long as 60 minutes.

Q8: How about the repeated positioning accuracy?

Answer: The repeated positioning accuracy of myArm 300 is ±0.5mm. The positioning of the two products is not the same. The ER 280 robotic arm is a consumer type and is mainly used in the education field. Using 1-2 hours to rest for 15-30 minutes is recommended. The repeat positioning accuracy can reach ±0.2mm in a short time. The ER 320 is suitable for commercial work within 12 hours, with a repeat positioning accuracy of ±0.3mm. If used quickly, the repeat positioning accuracy can also reach ±0.2mm.

Q9: Is there a camera on the robotic arm? And is there a visual recognition sorting function?

Answer: The robotic arm does not have a camera, but machine vision-related kits are now available for vision development.

Q10: Hello, can you provide relevant information about the robot arm of Elephantrobotics and post a tutorial?

Answer: GitHub development Link ( software tutorial ) is https://github.com/elephantrobotics/myCobot/

Reviews

There are no reviews yet.