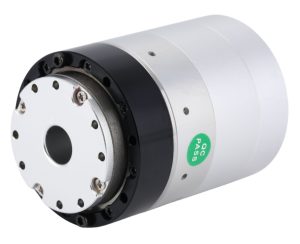

Humanoid Ankle Wrist Shoulder Hip Knee Planetary DC Robot Joint Motor

The Humanoid Joint Planetary Joint Module is a core component of robotic power systems. Through a highly integrated design combining a planetary reducer, frameless torque motor, brake, encoder, and driver, it achieves significant optimization in volume and weight, enabling precise motion control of the joint. This results in greater torque, smaller size, and lighter weight. Compared to harmonic joint modules, the planetary joint module features a smaller reduction ratio, higher output speed, and greater torque density, making it more suitable for medium- to low-load applications. We also provide customization services tailored to clients’ specific requirements.

Features

- High Torque Density and Power Performance: Multi-stage planetary reduction structure. Through a multi-stage gear combination, torque density can reach above 20N·m/kg, making it suitable for the high-load driving requirements of robotic hip joints, legs, and other parts.

- Impact Resistance and High Reliability: Peak torque output: Delivers greater peak torque output, meeting instantaneous power demands in dynamic motion scenarios.

- Advantages of planetary gear transmission: Gear meshing disperses impact force, can withstand harsh working conditions such as emergency stops and high-frequency load changes, and is suitable for high-dynamic scenarios like bipedal robot walking and jumping.

- Mass production controllability: The Planetary reducer solution has mature technology with high mass production consistency and reliability, suitable for large-scale applications.

- Compact Structure and Lightweight Design: High integration is achieved through a nested design of the planetary reducer, frameless motor, encoder, and other components, reducing volume by 30% compared to traditional solutions.

- Lightweight materials: Uses high-strength alloys and compact layout to meet humanoid robots’ stringent requirements for lightweight and high energy efficiency.

- High Precision and Low Energy Consumption: Low cogging torque and dual encoder closed-loop: Reduces torque ripple, combined with dual absolute encoders (motor end + output end), achieves ±0.05° repeat positioning accuracy.

- Transmission efficiency optimization: The planetary reducer achieves a transmission efficiency of above 80%.

- Multi-Axis Coordinated Control: Supports the CAN bus protocol to meet the multi-degree-of-freedom coordinated motion requirements of robots.

- Economy and Maintenance Convenience: Maintenance-free design: Stable planetary reducer structure requires no regular lubrication, reducing long-term usage costs.

- Modular interfaces: A standardized design facilitates quick replacement and upgrades, thereby shortening robot development cycles.

Specifications

| Model | Size | Reduction Ratio | Rated Torque (N·m) | Peak Torque (N·m) | Rated Speed (RPM) | Peak Speed (RPM) | Resolution (Motor/Gearbox) | Communication Interface | Encoder Repeatability (Arcsec) | Power Supply (V DC) | Hollow Shaft Diameter(mm) |

| mm | / | N.M | N.M | RPM | RPM | bit | Arcsec | V(DC) | mm | ||

| JRM-C4054-006 | 40-54 | 006 | 1 | 3 | 350 | 350 | 17bit(131072bit) | CAN | 40 | 48V | / |

| JRM-C40-66-036 | 40-66 | 036 | 6 | 18 | 50 | 50 | 17bit(131072bit) | CAN | 40 | 48V | / |

| JRM-C5070-020 | 50-70 | 020 | 6 | 19 | 170 | 170 | 17bit(131072bit) | CAN | 40 | 48V | / |

| JRM-C6070-020 | 60-70 | 020 | 12 | 40 | 150 | 150 | 17bit(131072bit) | CAN | 40 | 48V | ø5 |

| JRM-C7069-22.5 | 70-69 | 22.5 | 20 | 60 | 170 | 170 | 17bit(131072bit) | CAN | 40 | 48V | / |

| JRM-C8078-024 | 80-78 | 024 | 30 | 95 | 100 | 100 | 17bit(131072bit) | CAN | 40 | 48V | ø5 |

| JRM-C9579.6-008 | 95-79.6 | 008 | 18 | 60 | 400 | 400 | 17bit(131072bit) | CAN | 40 | 48V | ø5 |

| JRM-C9579.6-024 | 95-79.9 | 024 | 50 | 200 | 120 | 120 | 17bit(131072bit) | CAN | 40 | 48V | ø5 |

| JRM-C10483.5-20.4 | 104-83.5 | 20.4 | 50 | 300 | 150 | 150 | 17bit(131072bit) | CAN | 40 | 48V | ø8 |

| JRM-C12588-020 | 125-88 | 020 | 80 | 360 | 150 | 150 | 17bit(131072bit) | CAN | 40 | 48V | / |

| JRM-C12588-024 | 125-88 | 024 | 90 | 450 | 120 | 120 | 17bit(131072bit) | CAN | 40 | 48V | ø8 |

| Note: Peak torque refers to instantaneous output for up to 5 seconds. For continuous operation, please select the rated torque. Excessive use of peak torque may cause product damage. | |||||||||||

Reviews

There are no reviews yet.