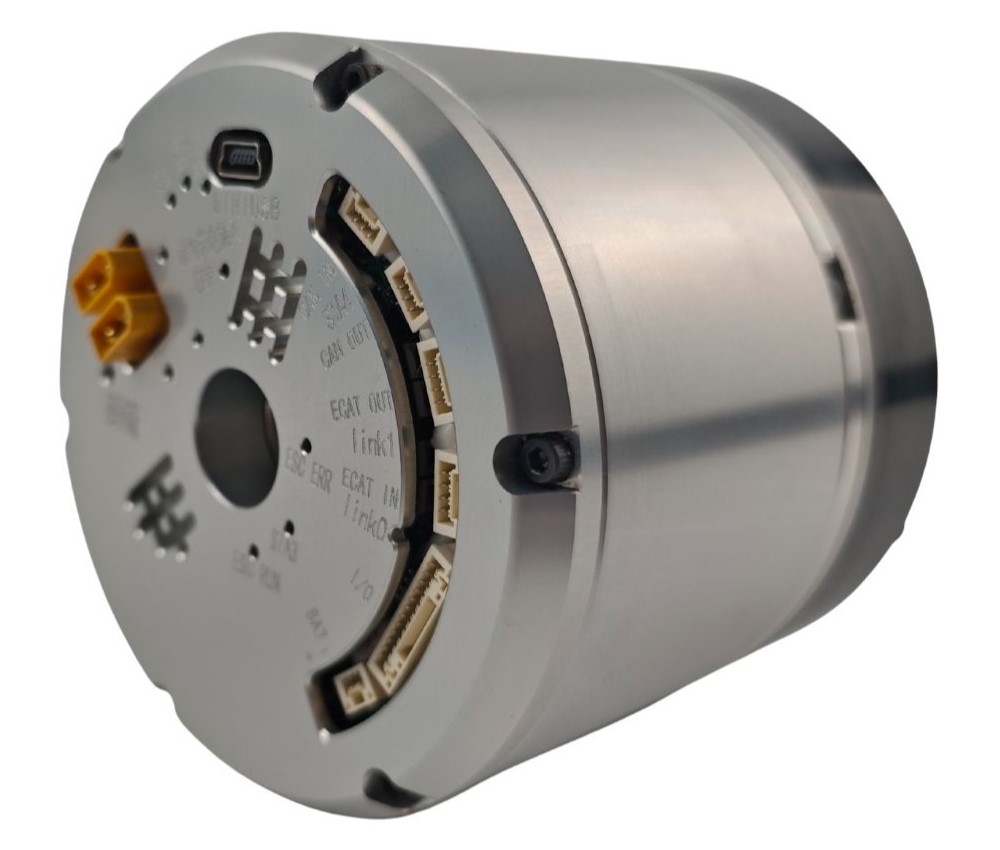

Ethercat Can Protocol Harmonic Drive Precision Drive Motor

In terms of communication speed, the maximum rate of the CAN protocol is 1 Mbps. This speed meets basic requirements in small to medium-scale applications but reveals performance bottlenecks when dealing with multi-motor coordinated control. For instance, in an application with 10 motors, the CAN communication cycle typically operates around 500 Hz. However, influenced by factors such as communication content complexity and packet transmission uniformity, this cycle cannot be guaranteed stable. It may fluctuate, thereby affecting the motion synchronization of harmonic drive motors.

Furthermore, the CAN protocol employs a “Carrier Sense Multiple Access with Collision Detection” (CSMA/CD) mechanism. As the number of devices on the bus increases, the probability of data transmission collisions rises. This not only extends the communication cycle but may also lead to data loss, posing certain operational risks for harmonic drive motors that require precise control. In terms of wiring and cost, while CAN supports a bus topology that simplifies wiring, its transmission distance is limited at high speeds (typically not exceeding 40 meters). If covering an extensive robotic system requires additional repeater devices, the overall cost may conversely increase.

Features

- Superior precision and zero backlash

- High Precision and Zero Backlash

- Zero-backlash design eliminates transmission clearance of traditional reducers, achieving repeat positioning accuracy of ±10 arcsec and absolute positioning accuracy of ±30 arcsec, suitable for precision motion control scenarios (e.g., surgical robots, collaborative robotic arms).

- 3D Conjugate Dual-Arc Tooth Profile Technology

- Optimizes tooth profile structure, reduces vibration and noise, improves transmission stiffness and service life, enabling smoother and more precise robot movements.

- Highly Integrated, Compact, and Lightweight Design

- Compact size and light weight: The high integration of the harmonic drive and frameless torque motor results in a compact structure, suitable for space-constrained scenarios (e.g., robot wrists, head joints).

- Lightweight material application: Uses high-strength aluminum alloy, carbon fiber, and other materials to reduce weight and improve robot energy efficiency and flexibility.

- High Transmission Efficiency: Transmission efficiency exceeds 80%, reducing energy loss and supporting efficient power transmission under dynamic load changes.

- High Safety and Reliability

- Torque sensor integration (customizable)

- It supports collision detection and drag teaching functions, enhancing human-robot collaboration safety.

- Impact resistance and long service life: The harmonic drive can withstand high-load emergency stops and is designed for a precision lifespan exceeding 10,000 hours, making it suitable for harsh industrial environments.

- Intelligent Integration and Control: Embedded controller with multi-protocol compatibility: Supports communication protocols like EtherCAT and CANopen, enabling dynamic PID adjustment.

Modular design: Standardized interfaces facilitate quick integration and maintenance.

Only logged in customers who have purchased this product may leave a review.

Shipping Policy

To minimize or avoid tariffs, we ship from the country where the product is made, such as China, Italy, or Taiwan.

Fast Delivery! We ship via FedEx, UPS, DHL, and USPS because they're fast, reliable, and easy to track. We process orders within 24 hours, and delivery may take 4-7 working days, depending on your location. We'll email you the tracking number once your order is shipped. We sell in USD.

Shipping Costs: For some industrial products, such as heavy wheels and CNC machines, we calculate shipping costs by weight rather than quantity. To reduce shipping costs for orders with multiple items, please email us at sales@ozrobotics.com before placing your order. We show shipping rates on the product page under the SHIPPING tab. To view the shipping cost for your country, click 'Add to Cart' on the product page.

Return Policy

5 Hours: Mistakes happen when ordering, so you have 5 hours to request a refund for any reason, including if you don’t want to pay the tariff. However, Stripe will not refund you their processing fee if you cancel your order.

All Sales Are Final: After 5 hours, we cannot cancel your order or issue a refund because order cancellations incur multiple transaction processing fees from Stripe and PayPal, additional shipping fees, and reverse tariff payments, which are costly and time-consuming. For technical issues, we will be happy to assist you in resolving problems and provide a replacement if you can prove that the product has a manufacturing defect.

Exchange Policy: We want you to be happy with your new purchase. However, once you have used the product, we cannot issue a refund. However, we will offer an exchange for a product with irreversible manufacturing defects or technical issues. If you purchased the wrong product, then you, as the customer, will be responsible for the re-shipping fees and tariffs. If the product you purchased is defective, email us at support@ozrobotics.com with photos or a video of the faulty parts so we can evaluate the issue before arranging a replacement.

Privacy Policy

Oz Robotics does not collect personal data from customers or visitors; it collects only the data shown on the user profile screen for registered users.

Terms and Conditions

If you were not at home or at your shipping address during the parcel delivery: It is not our or the supplier's fault; if the shipping/delivery company could not deliver your parcel because you, the customer, were not at home or at your delivery address on the delivery date/time, and as a result, the carrier returned your parcel to the manufacturer from where it was shipped. Please note that we do not accept excuses; you will therefore have to pay the re-shipping fee and the tariff for any re-shipment request. In such a case, we will not issue a refund. Please always check your spam folder to ensure you receive emails from Oz Robotics and shipping companies.

Product Warranty: Our warranty covers only product-related problems caused by manufacturing defects. It does not cover problems resulting from faulty repair attempts, customer accidents, or misuse.

Reviews

There are no reviews yet.