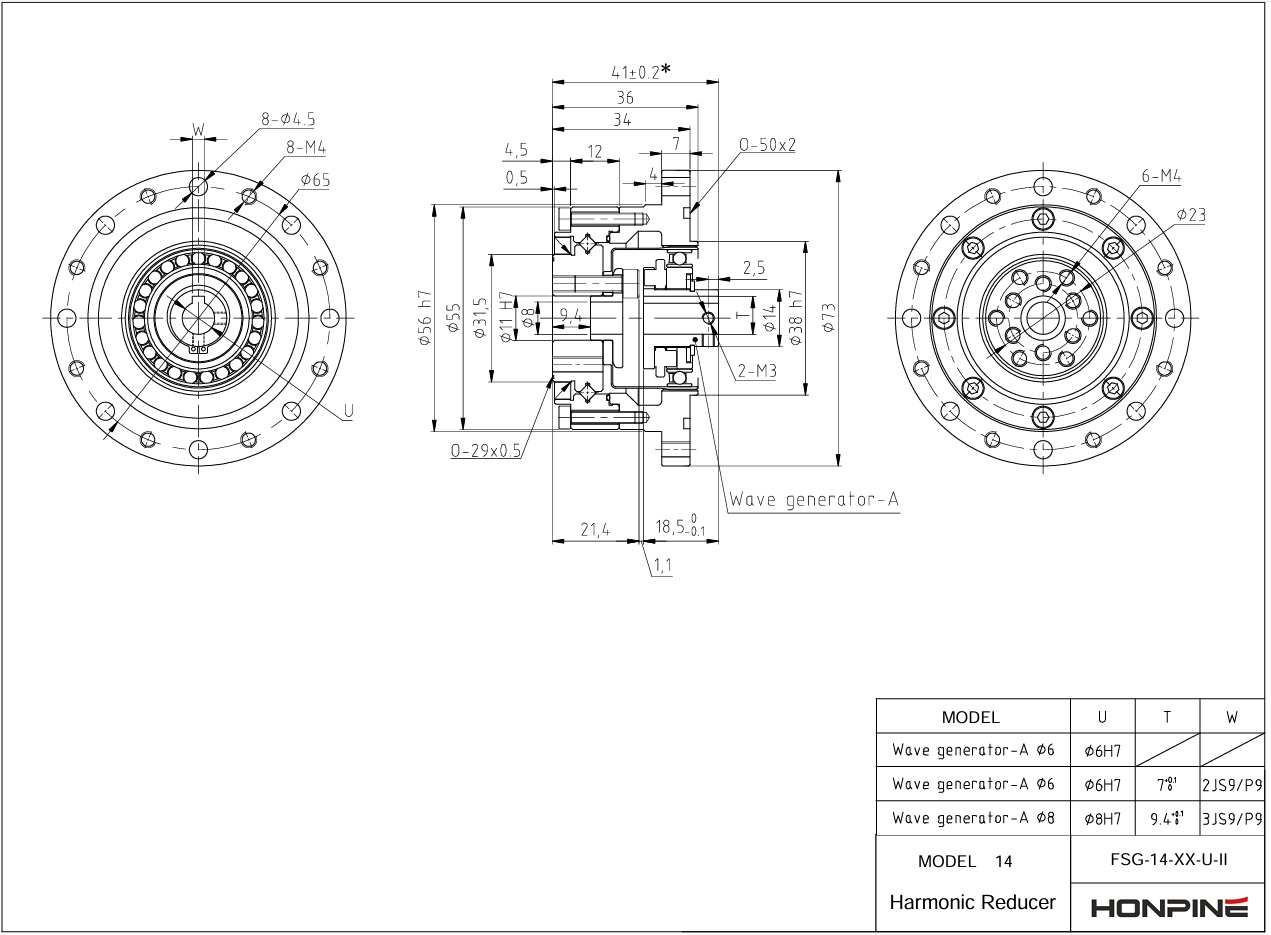

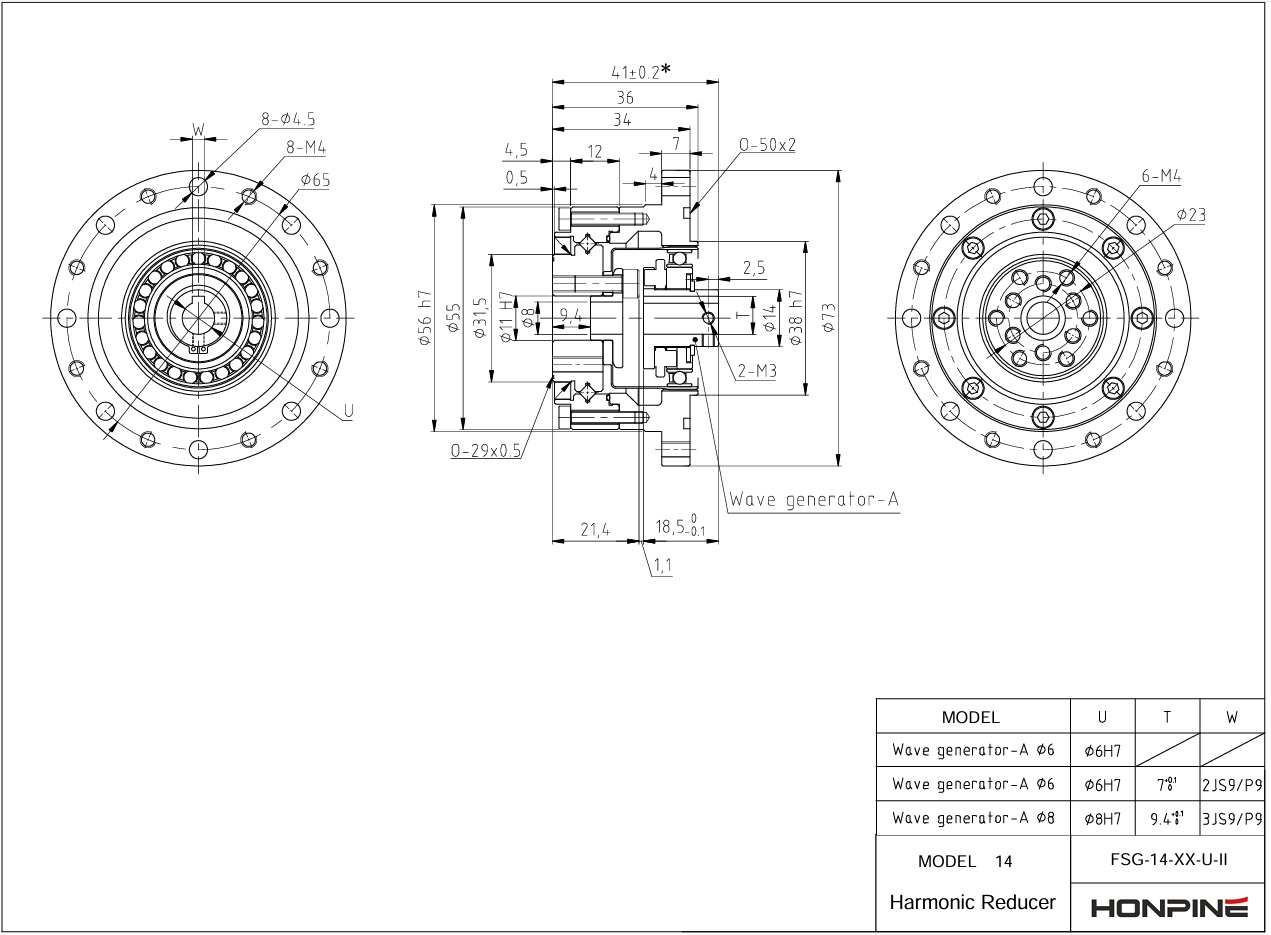

FSG-II-14 Cup Style Easy Installation Harmonic Drive Reducer Gearbox

The FSG-II series strain wave gear utilizes a cross-slider coupling mechanism for its wave generator. The camshaft bore dimensions can be customized to accommodate specific motor models. The input shaft directly engages with the wave generator’s inner bore through a keyed connection. This configuration is typically implemented with the circular spline fixed at the base and the flexspline serving as the output end.

Features

- The wave generator adopts an integrated cam structure, which provides greater tolerance to machining precision of components, enables self-aligning capability, and maintains coaxial alignment within required specifications.

- Higher torque capacity with optimized compact design

- Excellent rotational and positioning accuracy

- Coaxial input and output

- Commonly used in robotic arm end-effectors or sealed rotary tables

| Starting torque of the FSG series unit:cNm |

Reduction ratio Reduction ratio |

11 |

14 |

17 |

20 |

25 |

32 |

40 |

| 50 |

— |

4.5 |

6.7 |

8.6 |

17 |

34 |

61 |

| 80 |

— |

3.1 |

4.4 |

5.4 |

10 |

21 |

39 |

| 100 |

— |

2.8 |

3.7 |

4.7 |

8.8 |

20 |

34 |

| 120 |

— |

— |

3.4 |

4.2 |

8 |

17 |

31 |

| 160 |

— |

— |

— |

3.6 |

6.9 |

15 |

26 |

| Model |

Design value |

Instant permissible value |

| FSG-14 |

Mb di 20Nm |

Mb max 40Nm |

| Ftdi 180N |

Ft max320N |

| Fa di 180N |

Fa max 320N |

| FSG-17 |

Mb di30Nm |

Mb max 60Nm |

| Ftdi230N |

Ftmax400N |

| Fa di 230N |

Fa max 400N |

| FSG-20 |

Mb di42Nm |

Mb max 80Nm |

| Ftdi 270N |

Ftmax 480N |

| Fa di 270N |

Famax 480N |

| FSG-25 |

Mb di 80Nm |

Mb max 160Nm |

| Ft di440N |

Ft max 770N |

| Fa di 440N |

Fa max770N |

| FSG-32 |

Mb di 220Nm |

Mb max 440Nm |

| Ftdi 900N |

Ft max 1600N |

| Fa di900N |

Fa max 1600N |

| FSG-40 |

Mb di 320Nm |

Mb max 650Nm |

| Ftdi 1000N |

Ft max 1750N |

| Fa di1000N |

Fa max 1750N |

Only logged in customers who have purchased this product may leave a review.

Shipping Policy

To minimize or avoid tariffs, we ship from the country where the product is made, such as China, Italy, or Taiwan.

Fast Delivery! We ship via FedEx, UPS, DHL, and USPS because they're fast, reliable, and easy to track. We process orders within 24 hours, and delivery may take 4-7 working days, depending on your location. We'll email you the tracking number once your order is shipped. We sell in USD.

Shipping Costs: For some industrial products, such as heavy wheels and CNC machines, we calculate shipping costs by weight rather than quantity. To reduce shipping costs for orders with multiple items, please email us at sales@ozrobotics.com before placing your order. We show shipping rates on the product page under the SHIPPING tab. To view the shipping cost for your country, click 'Add to Cart' on the product page.

Return Policy

5 Hours: Mistakes happen when ordering, so you have 5 hours to request a refund for any reason, including if you don’t want to pay the tariff. However, Stripe will not refund you their processing fee if you cancel your order.

All Sales Are Final: After 5 hours, we cannot cancel your order or issue a refund because order cancellations incur multiple transaction processing fees from Stripe and PayPal, additional shipping fees, and reverse tariff payments, which are costly and time-consuming. For technical issues, we will be happy to assist you in resolving problems and provide a replacement if you can prove that the product has a manufacturing defect.

Exchange Policy: We want you to be happy with your new purchase. However, once you have used the product, we cannot issue a refund. However, we will offer an exchange for a product with irreversible manufacturing defects or technical issues. If you purchased the wrong product, then you, as the customer, will be responsible for the re-shipping fees and tariffs. If the product you purchased is defective, email us at support@ozrobotics.com with photos or a video of the faulty parts so we can evaluate the issue before arranging a replacement.

Privacy Policy

Oz Robotics does not collect personal data from customers or visitors; it collects only the data shown on the user profile screen for registered users.

Terms and Conditions

If you were not at home or at your shipping address during the parcel delivery: It is not our or the supplier's fault; if the shipping/delivery company could not deliver your parcel because you, the customer, were not at home or at your delivery address on the delivery date/time, and as a result, the carrier returned your parcel to the manufacturer from where it was shipped. Please note that we do not accept excuses; you will therefore have to pay the re-shipping fee and the tariff for any re-shipment request. In such a case, we will not issue a refund. Please always check your spam folder to ensure you receive emails from Oz Robotics and shipping companies.

Product Warranty: Our warranty covers only product-related problems caused by manufacturing defects. It does not cover problems resulting from faulty repair attempts, customer accidents, or misuse.

Reduction ratio

Reduction ratio

Reviews

There are no reviews yet.