Electro Chemical Marking and Etching Machine EUmark Set 01

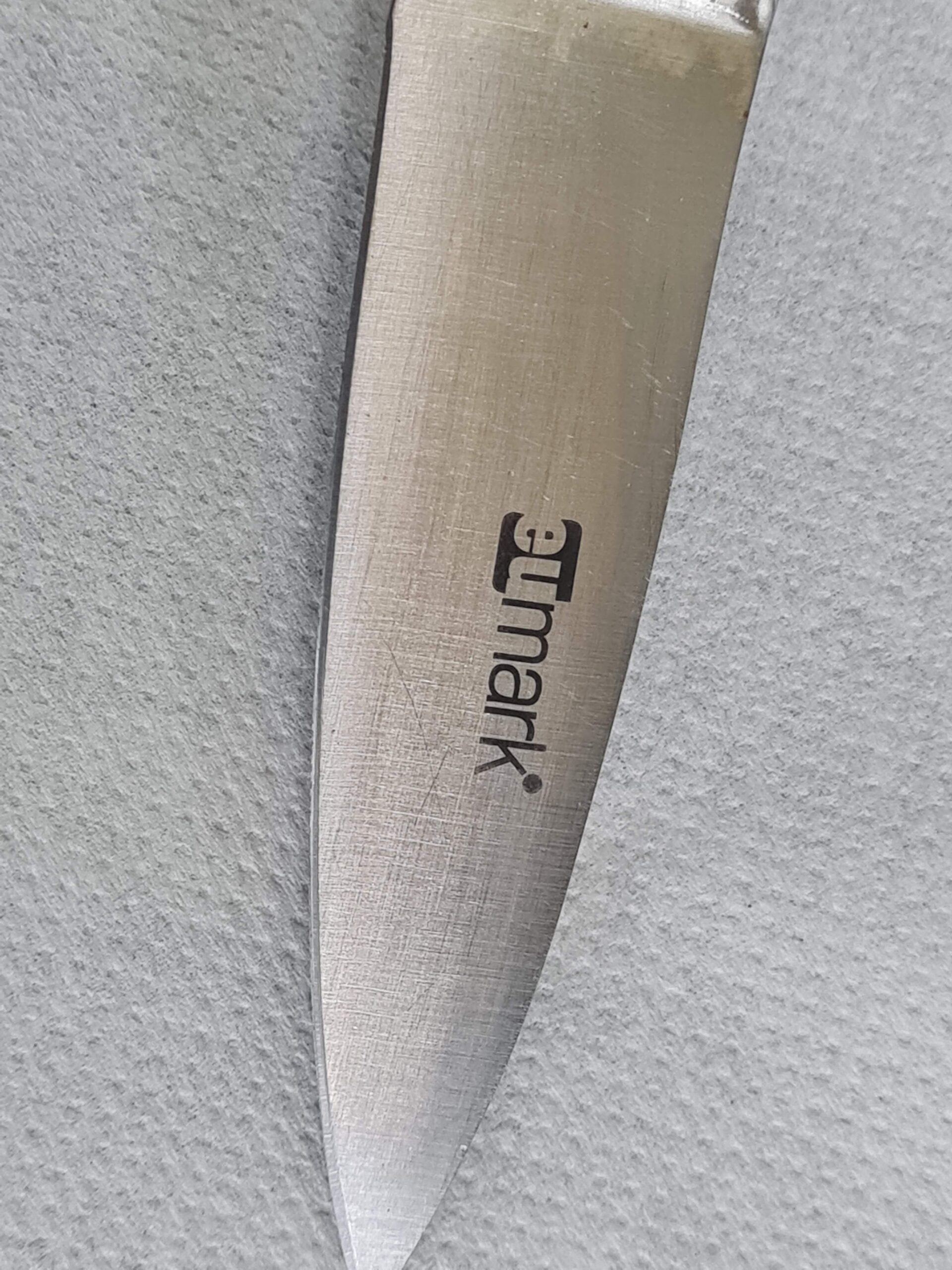

Mark and Etch Metal Surface Fast and Easy! With electrochemical marking, you can label your products in just a few seconds, whether you’re making knives, tools, or machine parts for the aerospace industry.

What is electrochemical marking?

Electrochemical marking is an electrochemical etching of metal surfaces using a small amount of electric current, an electrolyte, a marker with a pad to hold the electrolyte and carry the current, and a stencil with the required image.

Mark and Etch Metal Surfaces Fast and Easy

Whether you’re making knives, tools, or machine parts for the aerospace industry, with electrochemical marking you can mark and label your products in just a few seconds

What is electrochemical marking/etching?

Electrochemical marking is the fastest method for permanent marking of conductive metal surfaces. It produces a sharp, clean, and attractive mark in a matter of seconds without damaging the material.

Mark/etch the metal surfaces in 5 simple steps

- Turn on your EuMark machine.

- 2. Apply the electrolyte to the marker pad

- 3. Place the stencil (mask) with the required design on the metal

- 4. Press the marker pad against the stencil

- 5. 4 seconds later your desired design is permanently transferred onto your product

Electrochemical marking facts (fast, cheap, simple, safe, and high-quality)

Electrochemical marking is the fastest technique for permanently marking conductive metal surfaces. It produces a sharp, clean, attractive, and economic mark without damaging, stressing, or distorting the marked piece. The print is durable and edgeless. There is no corrosion or other adverse effect on the material. The process takes only a few seconds, and the marks are about 0.025 mm deep. Depending on the function and electrolyte selected, you can achieve clear etch marks, black oxide marks, or white marks on chemically blacked components. The piece’s shape can be flat, round, solid or hollow, assembled or un-tight. The equipment is very reliable, long-lasting, and suits many industrial needs. The process is straightforward, doesn’t require a lot of space, can be performed during manufacturing or before delivery, doesn’t require any special training, and is very safe.

Where can you use electrochemical marking?

A wide range of manufacturers uses electro-marking. For example, the process is used extensively to mark cutlery, tools, taps, drills, saw blades, and the automotive and air industries. Also, small businesses, hobbyists, and artists can use electro-marking.

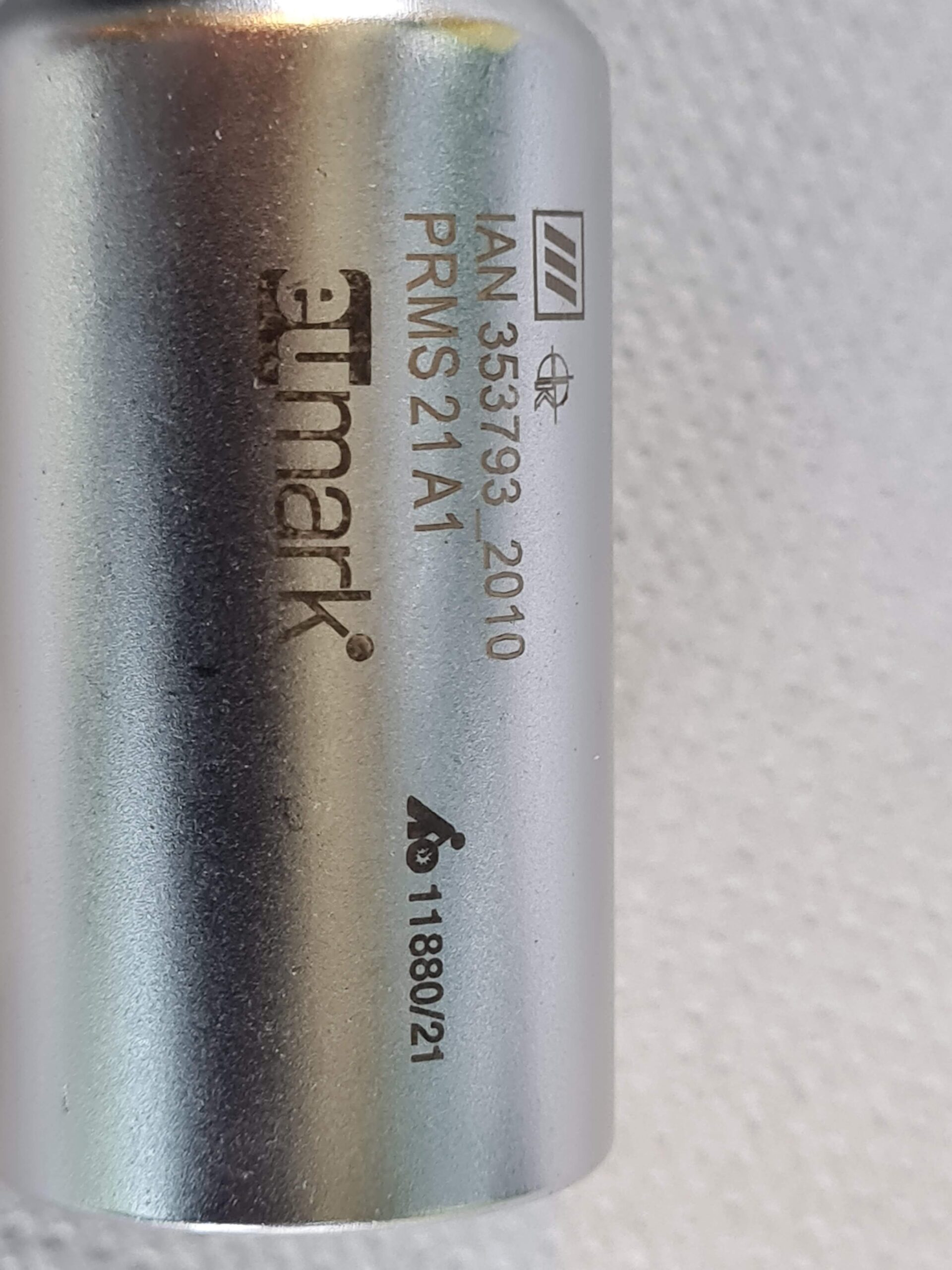

Electrochemical Marking Equipment

- They were marking devices. This unit you can find in more variants depending on size and specific needs. The basic models are different by possible operating modes, controllers for an automatic or semi-automatic operation, etc.

- Marker with pad Markers with pads can be manual, semi-automatic, and automatic. They are used to hold the stencil, the supply of electrolytes, and to close an electric circuit to be marked.

- Stencil Small, thin piece of a unique material containing the required design. There are two basic models: a long-lasting stencil with high resolution (can be used up to 5000 marks) and a short (fast) stencil for quick marking in small series.

- Electrolyte. These harmless salt solutions are used to conduct current and necessary chemicals for clearing each mark or black or white oxide mark. a. Cleaner These solutions are used for removing the rest of the electrolyte after the marking to reduce corrosion.

Reviews

There are no reviews yet.