Not Found

The page or the product you are looking for is no longer available. Please see other products: https://ozrobotics.com/shop/

Browse Hottest Products

-

DIY Aircraft Mechanical Model Kit

Sale! Original price was: $89.00.$59.00Current price is: $59.00. Brand: METAL-TIME INC.

-

GTR Simulator GTA Revolution – Adjustable Racing Cockpit with Leatherette Special Black and Red Seat

$1,169.99 Brand: Abtivan

-

GTR Simulator GTA Revolution – Adjustable Racing Cockpit With Leatherette Pista Black and Blue Seat

Sale! Original price was: $1,369.99.$1,299.99Current price is: $1,299.99. Brand: Abtivan

-

CubeMars AKA10-9 KV60 BLDC Motor for Robot with V3.0 Driver Board for AGV

$798.90 Brand: CubeMars

-

T-MOTOR U3 KV700 BLDC Brushless Waterproof Motor for Drones and Multi-Rotor UAVs

$109.90 Brand: LigPower

-

BleuIO PRO – Bluetooth Low Energy 5.2 USB Adapter – Blue

$35.00 Brand: Smart Sensor Devices

-

Ola Smart Security Camera with 5 Year Warranty

$259.99 Brand: Ola USA

-

HibouAir CO2 Sensor – Air Quality Indoor Monitor

Sale! Original price was: $149.00.$109.00Current price is: $109.00. Brand: Smart Sensor Devices

-

Ola Smart Security Camera

$199.99 Brand: Ola USA

-

NetIOLabs LoRaWAN Remote Pressure Monitoring

$520.00 Brand: ThingsLog

-

ThingsLog NB-IoT MQTT Water Level Monitoring Data Logger

$635.00 Brand: ThingsLog

-

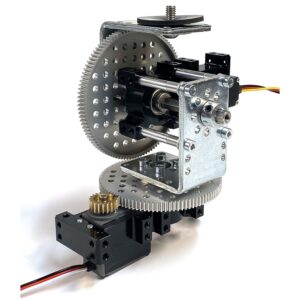

Heavy Duty Pan Tilt Mechanism – PT MECH-HD

$1,600.00 Brand: Inspector Bots

-

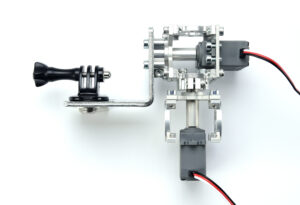

Pan Tilt Mechanism – PT MECH-Basic

$399.00 Brand: Inspector Bots