Push Button Cell Phones Push Button Mobile Phone

Technology News

Push Button Cell Phones Push Button Mobile Phone

Car Diagnostic Tool with OBD2 Scanner Bluetooth and All System Bidirectional Scan and OE Level

AI-Powered and Wireless Industrial Fiber Laser Engraver

Wireless Gateway with Display Screen

Off-Road Electric Bike

Lamborghini Hoverboard with Lights and App Two-Wheel Self-Balancing Scooter

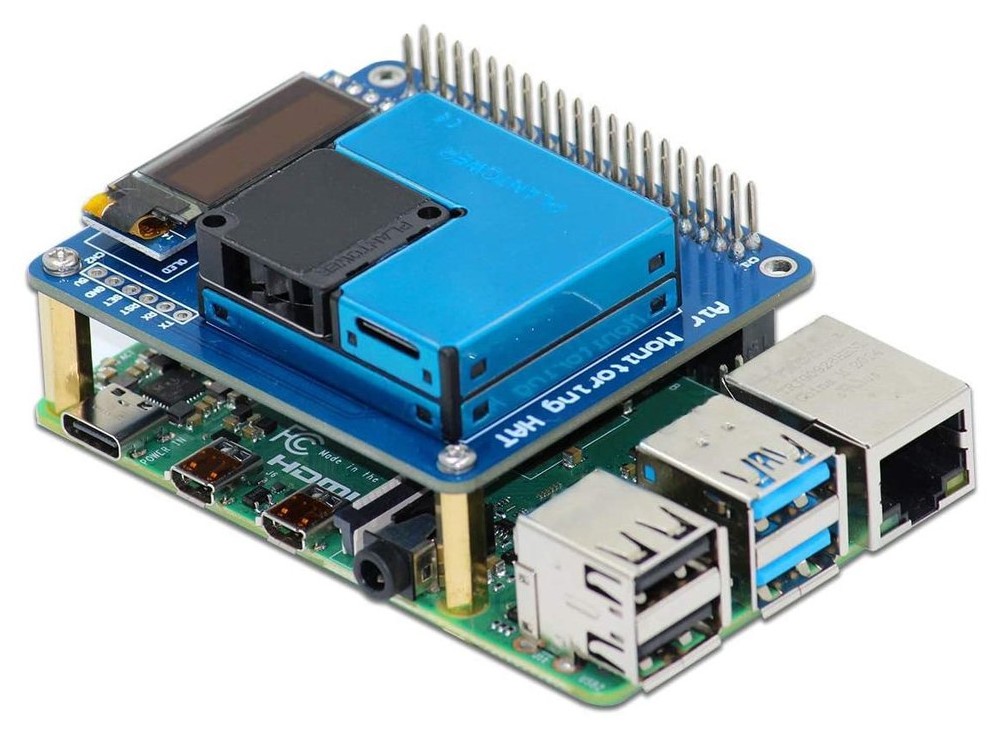

Sensor Air Monitoring HAT for Raspberry Pi

VTOL Airplane Drone Motor

VTOL Drone FPV Motor

Short Shaft VTOL Airplane Drone Motor