HeatSign Benchtop Dot Peen Marking System with Metal Engraving Machine

HeatSign HS-DE03 Dot Peen Metal Marking System represents a quick solution for your metal parts engraving marking requirements, such as nameplate marking. Featuring a high writing speed, the ability to work on a vast range of different metal parts materials, easy to use software; install it on your computer and connect the machine to work. In addition, the dot peen marker machine is stable and versatile. The HS-DE series supply a big marking area of 140mm x 90mm(5.51 inches x3.54 inches).

Excellent Performance

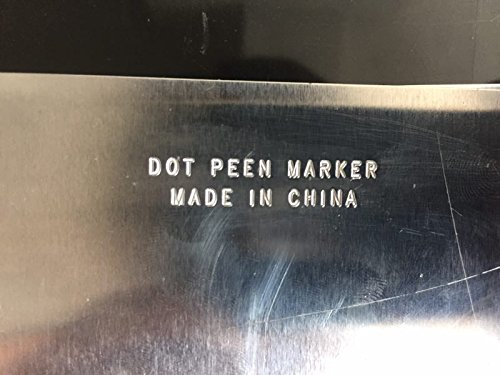

Being able to mark your products directly has huge advantages. By engraving your company name, the part number, or other technical information directly onto your products, you ultimately make them easier to use for your customers. In addition, even the most durable labeling systems cannot achieve the permanence of engraving, making it the preferred choice for information that needs to last. Common applications in which Dot Peen marking machines may be used include:

- Tool marking, name tag/label/dog tag engraving machine

- Marking automotive parts

- Marking forged and cast machine parts

- Marking batch numbers and other information on worked steel, copper, aluminum, etc.

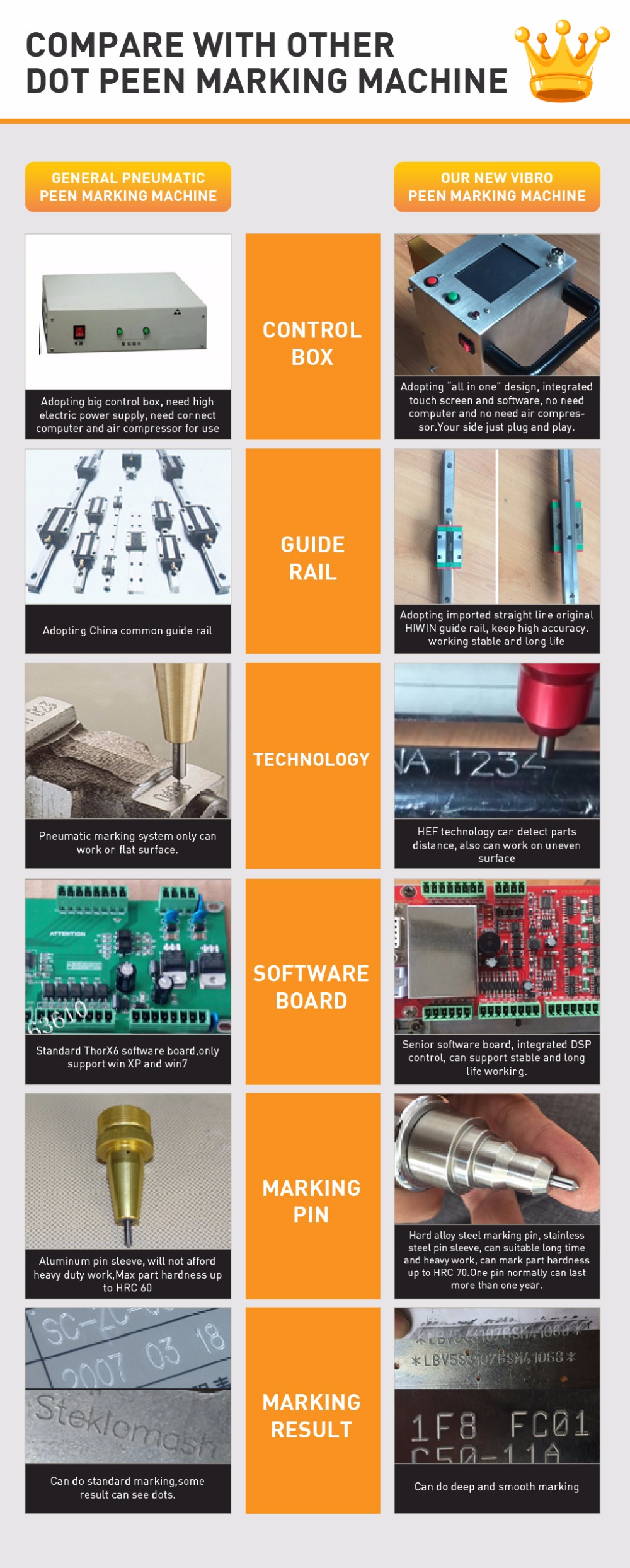

While speed and accuracy remain the primary concerns when considering any engraving machine, the HS-DE series incorporates several key technological advances that give it a number of significant advantages:

- The advanced HEF technology allows marking even on uneven surfaces, even relatively narrow pipes.

- The HS-DE series machines do not require discrete air compressor systems, facilitating compact installation suitable even for small workshops.

Similarly, controlling the HS-DE series machines is accomplished through an incorporated electric marking system; no separate air compressor is needed. This gives direct control of the machine and helps to minimize the compatibility and latency problems common on many other engraving machines.

The HS-DE series utilizes extremely hard tungsten alloy pins for marking. Even with heavy usage, these pins ensure error-free marking for up to a year. This reduces the cost of consumables, eliminating the possibility of misprints and errors, thus avoiding the necessity to discard incorrectly printed products. The machines are capable of printing a wide variety of characters and symbols. As standard, the English alphabet, numerals, graphics, logos, dot matrix 2D codes circled text, and a range of special symbols may all be printed.

HeatSign’s in-house experts are available to help with all aspects of choosing and installing HS-DE series machines. We can also complete bespoke installations, saving you the cost of sub-contracting installation by keeping this cost in-house.

Dot Peen Machine Advantages

- Applying the most widely used up-down lifting structure to mark different size metal parts.

- Software with a powerful edit function can automatically mark any logo, character, letter and graph, series number, VIN Number, or engine number.

- Adopt Imported guide rail, keep high precise marking, can mark very small characters

- Low consumption, one Hard Marking Pin can last at least one year

- HEF technology make it also works on an uneven surface

Technical Parameters

- Item Number: HS-DE03

- Engraving surface: Flat surface

- Marking area:140mm x 90mm

- Power source:100V~240V 50HZ/60HZ

- Power consumption:125W

- Software: Include

- Engraving machine type: Desktop, benchtop

- Engraving depth:0.02-0.6 mm (adjustable, depending on materials)

- Marking speed:2 letters~4 letters/s according to letter size (height 2mm)

- Marking materials request: Hardness less than HRC60

- Other Device request:Computer( software support WinXP,win7,win8,win10)

Applicable Materials

The pin marking machine can engrave all metals such as Aluminum, Steel, Stainless Steel, Copper, Brass, Gold, Iron, etc. It can also mark on hard plastics. It is mainly used for engraving and marking the natural part, nameplate, car chassis, VIN code, component identification, traceability, metal tag, label, cast, forge, rod, engine, gear, pump, etc.

Note: This machine should be plugged in and connected to the computer when used.

Reviews

There are no reviews yet.